ALL GOOD THINGS COME IN THREES: PERFORMANCE, COST, SUSTAINABILITY

The classic product development goals of “high performance” and “low costs” have been joined by “sustainability”, which has gone from being an optional “nice-to-have” to a cornerstone when planning new products. A cornerstone that must now be included on an equal footing with the other two goals.

On the one hand, strict and binding requirements from legislators, industry as sociations and environmental organisa tions are coming into force, such as the EU’s Corporate Sustainability Reporting Directive (CSRD). On the other hand, proven sustainability has become a factor in purchasing decisions in both B2B and B2C. The environmental climate crisis has f inally arrived in the engineering industry and there is an urgent need for action. But there are also opportunities

PRODUCT DEVELOPMENT TODAY

Change costs increase exponentially later in the product development process. This is where digital engineering comes in: In the earliest development phases, long before they physically exist, engineers optimize future products using detailed digital models.

Ideally, the future “performance” and the costs for components, production and use should be transparent from the outset. The ecological footprint is also defined through the choice of materials, designs and construction methods.

However, sustainability also has other facets that need to be quantified and dis closed – the legislator sends its regards:

- The CO2 footprint for transportation, production and operation

- Other environmental impacts, e.g. through the use of critical substances

- Aspects of disposal and the circular economy

- The social impact

How can such variables be incorporated into digital engineering at an early stage and optimized in line with performance and costs? How does “Design for Sustain ability” succeed?

SUSTAINABILITY – THE NEW KID ON THE BLOCK

Today, most of these properties are only recorded, documented, accumulated and evaluated in the course of the product’s life. They are recalculated once the product is already there, often with information from mixed sources.

The consequences, i.e. the analysis of what needs to be done better and the implementation, therefore often follow on an uncertain data basis, typically within the next few product generations. This can be risky, and is at the very least a painful loss of time to achieving sustainability goals and a missed opportunity in terms of innovation and sales. What’s more, specifications, rules and laws change over time, are not always uniform and may be missed again if properties are updated too late.

DIGITIZED MATERIAL INTELLIGENCE CREATES TRANSPARENCY

“Design for sustainability” means taking a forward-looking approach to the issue of sustainability. However, the integration of a product’s life cycle assessment at a very early stage of the development process is still in its infancy. Apart from the lack of pressure to act, the reasons for this lie in the complexity of such data and the dynamic nature of the criteria

The materials used to manufacture a product are critical regarding sustaina bility aspects: Without materials, there is no physical product. Materials must be extracted, purchased, transported and pro cessed; Materials shape a product and its “life” – and thus the Life Cycle Assessment (LCA) – right up to the end of its life and the question of whether they need to be reused, recycled or disposed of.

All of this contributes to the sustainability of the product must be disclosed in accordance with the CSRD and other directives such as REACH or RoHS, with regard to environmental impact and including the supply chain

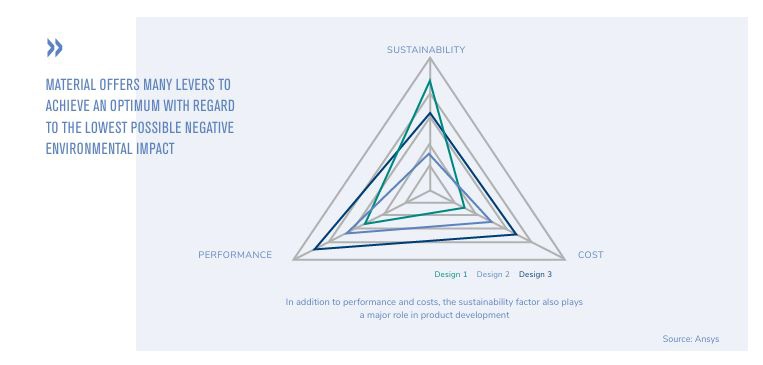

At the same time, however, material also offers many levers to achieve an optimum with regard to the lowest possible negative environmental impact: As a trade-off to performance and costs or – keyword: innovation – even as a driver for a competitive advantage through better performance and higher revenues, because proven sustainability is rewarded by the customer.

Digital material intelligence means consistency. Data is recorded and used according to a uniform structure. Decisions are always made on one and the same database, the “single source of truth”. This applies to design, when materials are selected, CAE engineers who evaluate variants, purchasing and production, who ultimately realize the products exactly as planned.

CENTRAL, INTEGRATIVE, INTELLIGENT

With the Ansys Granta MI product – MI stands for “Material Intelligence” – Ansys provides the framework for a central, up-to date and integrative source of information for all material knowledge within a company. Not as an isolated solution, but interlinked with all other digitized company processes, from CAD and CAE to PLM and ERP. A single, reliable and up-to-date company-wide – intelligent! – source on the subject of materials that all areas use and maintain – from R&D, materials management and testing to production, quality assurance, procurement and legal.

NEW: A MODULE FOR SUSTAINABILITY

In 2024, Ansys Granta MI received a new module that was developed specifically for the early implementation of important sustainability aspects: Ansys Granta MI Sustainability. The collection, linking and evaluation of all sustainability-relevant in formation in the context of materials enables companies to incorporate the environmental impact of future products into the development process at a very early stage and to report it as early as the marketing launch. Flexibly, reliably and in accordance with recognized standards and in-house specifications – and without losing sight of the effects on product performance and costs.

STRUCTURED MATERIAL SWARM INTELLIGENCE:

Material information is fundamentally complex and multi-layered; it often has to be painstakingly obtained, and the choice of materials is constantly increasing.

Regulations are constantly changing, they vary from region to region, and the number of substances classified as “harmful” is also growing. This also applies to purchased materials and supply chains.

Cost effects must be taken into account in the sense that the earlier the optimum mate- rial is found, the cheaper it is to develop; there are also dependencies on the service life of the product with very different interests among the parties involved.