Ansys for Computational Fluid Dynamics (CFD) Simulation

Ansys for Fluid Mechanics Simulation

Complete Fluid Mechanics Simulation Solutions with Ansys

Ansys Computational Fluid Dynamics (CFD) products are designed to help engineers make faster, more informed decisions. Our CFD simulation solutions are widely recognized for their exceptional computational power and accurate results. They enable reduced development time while enhancing product performance and safety.

Intuitive yet extremely powerful, Ansys Computational Fluid Dynamics (CFD) software accelerates product development and fosters innovation, even in the face of growing demands for optimization and reduced margins of error. With their user-friendly and modern interface, our tools make the simulation process more efficient and less complex.

Optimize your time and increase your productivity with Ansys CFD solutions. Our products enable remarkable progress through advanced technology, while meeting the growing demands for efficiency and performance.

Complete Fluid Mechanics Simulation Solutions with Ansys

Ansys Computational Fluid Dynamics (CFD) products are designed to help engineers make faster, more informed decisions. Our CFD simulation solutions are widely recognized for their exceptional computational power and accurate results. They enable reduced development time while enhancing product performance and safety.

Intuitive yet extremely powerful, Ansys Computational Fluid Dynamics (CFD) software accelerates product development and fosters innovation, even in the face of growing demands for optimization and reduced margins of error. With their user-friendly and modern interface, our tools make the simulation process more efficient and less complex.

Optimize your time and increase your productivity with Ansys CFD solutions. Our products enable remarkable progress through advanced technology, while meeting the growing demands for efficiency and performance.

Discover the flagship product: Ansys Fluent!

Ansys Fluent delivers accurate and reliable fluid simulation results.

Ansys Fluent, on the other hand, represents the pinnacle of fluid simulation with its advanced features. Fluent excels in the detailed analysis of fluid dynamics phenomena, offering unmatched accuracy and application flexibility across a wide range of complex scenarios. With its advanced algorithms and high-fidelity modeling capabilities, Fluent enables highly detailed simulations while ensuring fast computation times. This software fosters limitless innovation, allowing engineers to solve complex challenges efficiently and precisely. By combining speed, accuracy, and flexibility, Fluent supports the development of innovative, high-performance solutions in various fields, from aerospace to automotive, energy, and manufacturing.

Discover the flagship product: Ansys Fluent!

Ansys Fluent delivers accurate and reliable fluid simulation results.

Ansys Fluent, on the other hand, represents the pinnacle of fluid simulation with its advanced features. Fluent excels in the detailed analysis of fluid dynamics phenomena, offering unmatched accuracy and application flexibility across a wide range of complex scenarios. With its advanced algorithms and high-fidelity modeling capabilities, Fluent enables highly detailed simulations while ensuring fast computation times. This software fosters limitless innovation, allowing engineers to solve complex challenges efficiently and precisely. By combining speed, accuracy, and flexibility, Fluent supports the development of innovative, high-performance solutions in various fields, from aerospace to automotive, energy, and manufacturing.

HIGHLIGHTS

Discover the best fluid simulation tools available on the market within an efficient and customizable workspace.

Streamlined workflows

Accelerate your pre- and post-processing with streamlined workflows for meshing and application setups.

Fluent features customizable, task-based workflows for pre-processing to accelerate the process of generating high-quality meshes ready for CFD. These workflows apply to both clean and dirty CAD. Application workflows are streamlined to reduce the number of clicks and panels the user has to navigate. These workflows include multiphase modeling, batteries, shape optimization, aerodynamics, and much more.

Battery Modeling

Advance the design and safety of your batteries with fast and accurate simulation. Electrochemistry can be used to predict aging and lifespan. Thermal management and battery thermal runaway can be simulated to ensure optimal performance and safety. A Reduced Order Model (ROM) can be created by extracting key thermal characteristics to analyze temperature in just seconds.

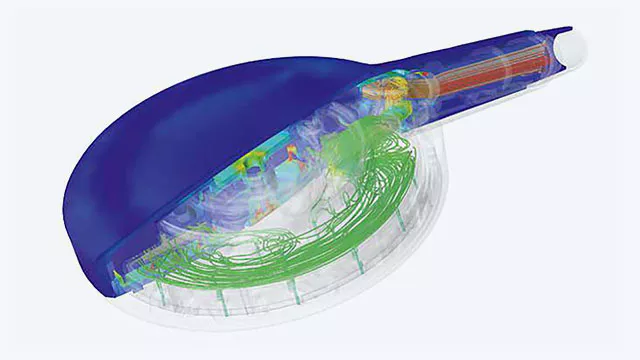

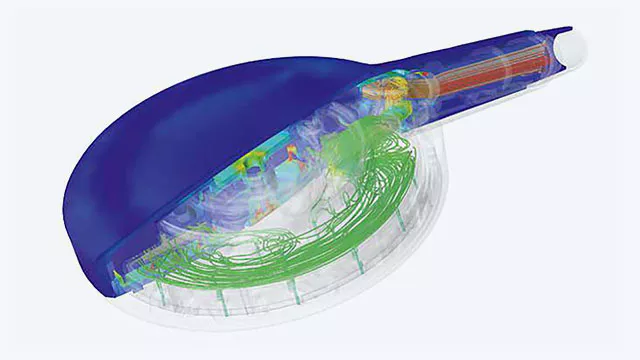

Electric Motor Cooling

Cooling of electric motors is critical when transitioning to higher power and high-efficiency equipment. Fluent can be used to identify the appropriate cooling mechanism for an electric motor. Optimize this method, whether it is natural cooling, water cooling, or spray cooling, to ensure that motor efficiency is not compromised and that the magnets are not damaged.

Turbulence Modeling

A wide range of turbulence models is available to choose the right one for your application. Fluent offers a comprehensive selection of turbulence models, including the Generalized k-ω (GEKO) model. GEKO is a groundbreaking concept with adjustable coefficients that can be tailored to different flow regimes.

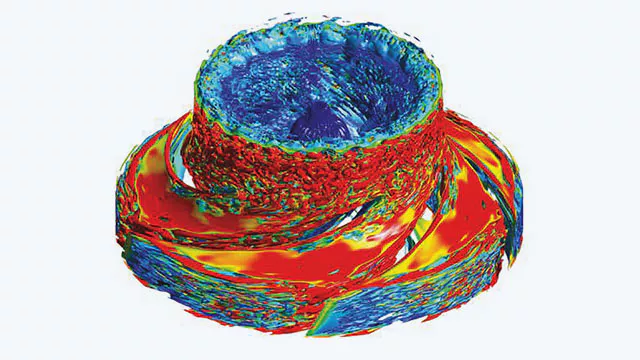

Multiphase Flows

Simulate multiphase flows with high accuracy, including gas-liquid, liquid-liquid, gas-solid flows, particle flows, and even DEM. Different modeling approaches are required when transitioning from single-phase to multiphase flow applications, and Ansys fully understands this.

To help you predict these complex flows with precision, we offer a wide range of models for gas, liquid, solid, particle, and even MNA (Multiphase Network Approach) flows, ensuring the most accurate results.

Fluid-Structure Interaction (FSI)

Predict fluid-structure interactions accurately under the influence of pressure and/or thermal loads. Solve your fluid-structure interaction (FSI) challenge to ensure your product is safe, reliable, and optimized. Fluent can solve FSI problems independently and integrates with Ansys Mechanical for the most complex simulations.

Combustion Models

Accurate combustion models enable a better understanding of system performance and flow phenomena. Ensuring precise combustion is critical for the accurate mixing of turbulence, chemistry, and their interaction. Fluent offers validated, high-fidelity reactive flow models for your combustion applications.

HIGHLIGHTS

Discover the best fluid simulation tools available on the market within an efficient and customizable workspace.

Streamlined workflows

Accelerate your pre- and post-processing with streamlined workflows for meshing and application setups.

Fluent features customizable, task-based workflows for pre-processing to accelerate the process of generating high-quality meshes ready for CFD. These workflows apply to both clean and dirty CAD. Application workflows are streamlined to reduce the number of clicks and panels the user has to navigate. These workflows include multiphase modeling, batteries, shape optimization, aerodynamics, and much more.

Battery Modeling

Advance the design and safety of your batteries with fast and accurate simulation. Electrochemistry can be used to predict aging and lifespan. Thermal management and battery thermal runaway can be simulated to ensure optimal performance and safety. A Reduced Order Model (ROM) can be created by extracting key thermal characteristics to analyze temperature in just seconds.

Electric Motor Cooling

Cooling of electric motors is critical when transitioning to higher power and high-efficiency equipment. Fluent can be used to identify the appropriate cooling mechanism for an electric motor. Optimize this method, whether it is natural cooling, water cooling, or spray cooling, to ensure that motor efficiency is not compromised and that the magnets are not damaged.

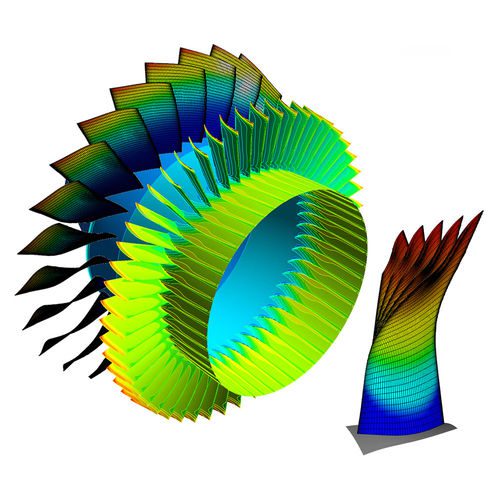

Turbulence Modeling

A wide range of turbulence models is available to choose the right one for your application. Fluent offers a comprehensive selection of turbulence models, including the Generalized k-ω (GEKO) model. GEKO is a groundbreaking concept with adjustable coefficients that can be tailored to different flow regimes.

Multiphase Flows

Simulate multiphase flows with high accuracy, including gas-liquid, liquid-liquid, gas-solid flows, particle flows, and even DEM. Different modeling approaches are required when transitioning from single-phase to multiphase flow applications, and Ansys fully understands this.

To help you predict these complex flows with precision, we offer a wide range of models for gas, liquid, solid, particle, and even MNA (Multiphase Network Approach) flows, ensuring the most accurate results.

Fluid-Structure Interaction (FSI)

Predict fluid-structure interactions accurately under the influence of pressure and/or thermal loads. Solve your fluid-structure interaction (FSI) challenge to ensure your product is safe, reliable, and optimized. Fluent can solve FSI problems independently and integrates with Ansys Mechanical for the most complex simulations.

Combustion Models

Accurate combustion models enable a better understanding of system performance and flow phenomena. Ensuring precise combustion is critical for the accurate mixing of turbulence, chemistry, and their interaction. Fluent offers validated, high-fidelity reactive flow models for your combustion applications.

Other Ansys Solutions for Fluid Mechanics Simulation

CADFEM – Your Unique Partner for Simulation

With over 35 years of experience in simulation, CADFEM is the ideal partner to cover the wide range of simulation types for structural mechanics.

Whether it’s static strength analysis or implementing specific material properties, you can benefit from CADFEM’s simulation expertise to solve your development tasks.

With more than 50 different training offerings, we provide you with the right knowledge to address your tasks in structural mechanics, thermal analysis, acoustics, and much more.

Get started quickly and according to your needs: advised by CADFEM, find the solution that suits you from our wide range of software and licenses, ranging from easy access via License as a Service to professional setups, including HPC cluster integrations.

For more information, please contact us.

CADFEM – Your Unique Partner for Simulation

With over 35 years of experience in simulation, CADFEM is the ideal partner to cover the wide range of simulation types for structural mechanics.

Whether it’s static strength analysis or implementing specific material properties, you can benefit from CADFEM’s simulation expertise to solve your development tasks.

With more than 50 different training offerings, we provide you with the right knowledge to address your tasks in structural mechanics, thermal analysis, acoustics, and much more.

Get started quickly and according to your needs: advised by CADFEM, find the solution that suits you from our wide range of software and licenses, ranging from easy access via License as a Service to professional setups, including HPC cluster integrations.

For more information, please contact us.

RÉFÉRENCES CLIENTS

Improving the Aerodynamics of Krone Semi-Trailers

Semi-trailers, along with their accessories, must comply with European regulations regarding CO2 emissions and fuel consumption, where aerodynamic drag plays a crucial role.

Through aerodynamic simulation, design modifications can be quickly analyzed and evaluated without the need for physical models or expensive wind tunnel tests. Krone engineers take advantage of Ansys CFD simulation tools to efficiently assess aerodynamic drag, integrating numerous components into their analyses.

This approach helps reduce costs and accelerate development timelines while optimizing aerodynamic performance.

Scaling and Optimization of Hydrogen Compressor and Storage

In hydrogen compressors, performance is measured by the compression ratio, storage capacity, and flow rate, with major challenges related to specifying design parameters to meet strict requirements. The Ansys Fluent software was used to perform coupled simulations of fluid dynamics and heat transfer, allowing for an in-depth understanding of complex phenomena and determining optimal parameters. Thanks to this approach, the design and operating conditions of the compressors were optimized, reducing manufacturing and operational costs while shortening product development cycles.

Geometric Modeling and Fluid-Structure Interaction

Old facilities require revisions due to changes in operating conditions. To optimize this revision, it is crucial to determine the new stresses exerted by the water flow. Using Ansys Design Modeler, a 3D model based on old construction plans was created. Pressure calculations made with Ansys CFD allowed the loads to be transferred to the finite element model in Ansys Mechanical, enabling the determination of structural stresses. Thanks to the expertise of CADFEM (Switzerland) AG, Grande Dixence S.A. was able to analyze the flow behavior and structural requirements according to the new operating conditions.

Extended CFD Applications

We have been using Ansys CFX for CFD for some time and would like to complement it in the future with Ansys Fluent to cover a broader range of applications.

CFD in Glider Construction

These experiences and the confidence we have gained through CFD are of great use to us. They confirm what we believed in many cases while showing us additional optimization potential.

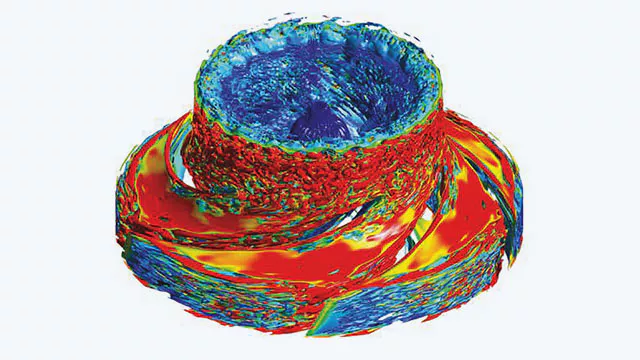

Pump Simulation

This special pump development in just eight months was only possible thanks to the coupled use of fluid and structural simulation. With such short development times, we could not perform tests on a test bench.

RÉFÉRENCES CLIENTS

Improving the Aerodynamics of Krone Semi-Trailers

Semi-trailers, along with their accessories, must comply with European regulations regarding CO2 emissions and fuel consumption, where aerodynamic drag plays a crucial role.

Through aerodynamic simulation, design modifications can be quickly analyzed and evaluated without the need for physical models or expensive wind tunnel tests. Krone engineers take advantage of the Ansys CFD simulation tools to efficiently assess aerodynamic drag, integrating numerous components into their analyses. This approach helps reduce costs and accelerate development timelines while optimizing aerodynamic performance.

Scaling and Optimizing Hydrogen Compressor and Storage

In hydrogen compressors, performance is measured by the compression rate, storage capacity, and flow rate, with major challenges related to specifying design parameters to meet strict requirements. The Ansys Fluent software was used to perform coupled simulations of fluid dynamics and heat transfer, providing an in-depth understanding of complex phenomena and determining optimal parameters. This approach optimized the design and operating conditions of the compressors, reducing manufacturing and operational costs while shortening product development cycles.

Geometric Modeling and Fluid-Structure Interaction

Aging facilities require revisions due to changes in operating conditions. To optimize this revision, it is crucial to determine the new constraints imposed by the water flow. Using Ansys Design Modeler, a 3D model based on old construction plans was created. Pressure calculations performed with Ansys CFD allowed for transferring loads to the finite element model in Ansys Mechanical, thus determining the structural constraints. Thanks to the expertise of CADFEM (Switzerland) AG, Grande Dixence S.A. was able to analyze the flow behavior and structural requirements under the new operating conditions.

Extended CFD Applications

We have been using Ansys CFX for CFD for some time now, and we would like to complement it in the future with Ansys Fluent to cover a broader range of applications.

CFD in Glider Construction

These experiences and the confidence we have gained through CFD are extremely valuable. They confirm what we thought in many cases while also showing us additional optimization potential.

Pump Simulation

This special pump development in just eight months was only possible thanks to the coupled use of fluid and structural simulations. With such short development times, we could not perform tests on a test bench.