HIGHLIGHTS

Discover dynamic analysis and take advantage of advanced solving options for a wide range of materials and features.

Linear Dynamics

Ansys Mechanical covers all your linear dynamic analysis needs, including modal, harmonic, spectral response, and random vibration with preload, offering advanced solver options for fast solutions.

Perform acoustic simulations to understand the vibroacoustic behavior of systems, with or without structural preload. Including preload enhances fidelity and allows for the simulation of self-weighted bolted assemblies, or even squealing brakes.

Non-Linearity

Beyond linear and elastic materials, you can simulate the behavior of materials when they undergo plastic or even hyperelastic deformation (materials such as rubber and neoprene).

Nonlinear simulation also takes into account contact and large deformation of parts moving relative to each other, with or without friction.

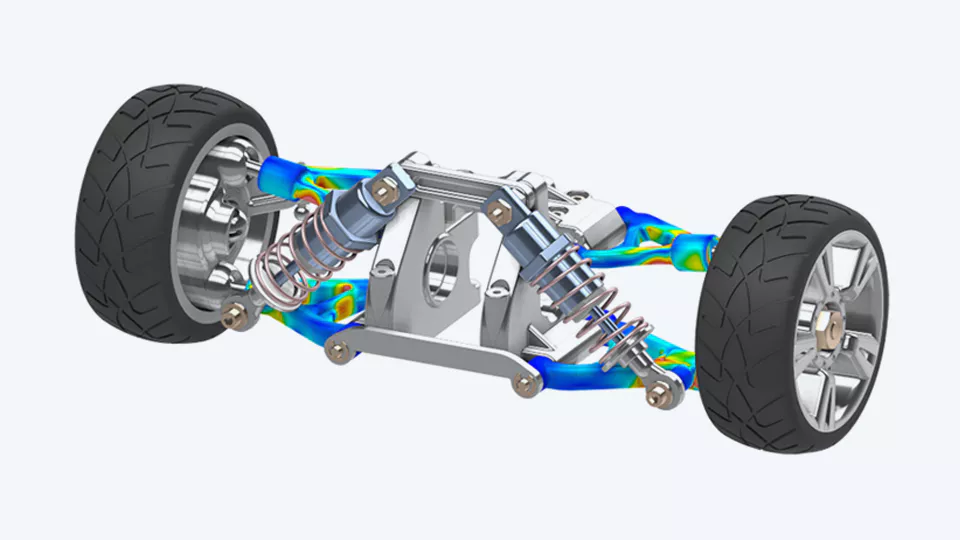

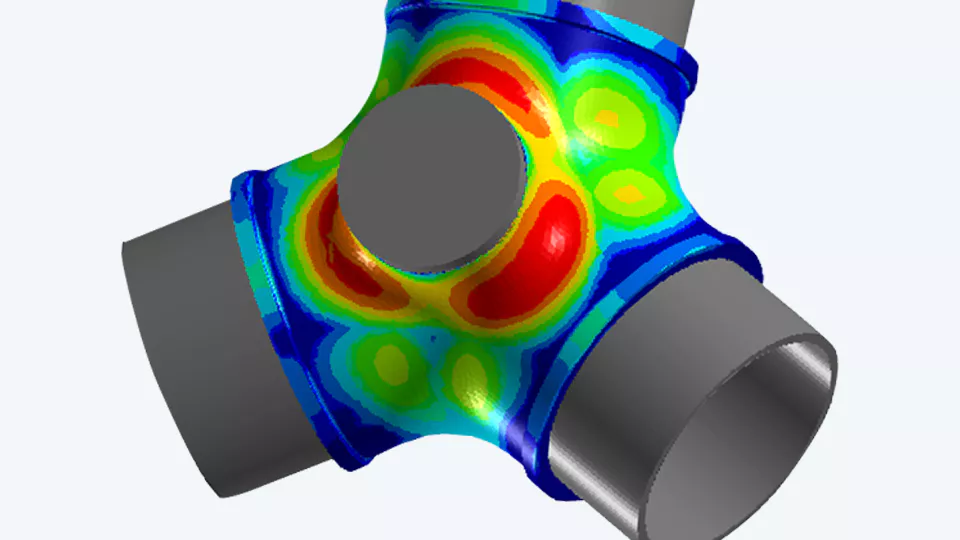

Contact

Ansys Mechanical offers a full range of contact features that allow you to account for interactions between multiple parts.

It can simulate everything, from bonded contact that treats joints between parts as if they were glued or welded, to contact interfaces that allow parts to separate and assemble with or without friction effects. Proper contact simulation enables the modeling of load path changes as parts deform and confidently predicts the behavior of assemblies in the real world.

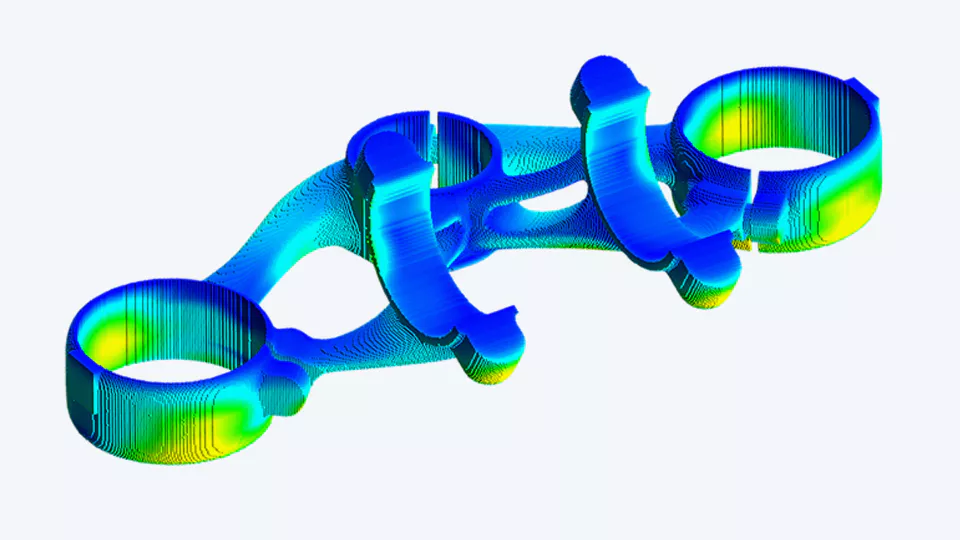

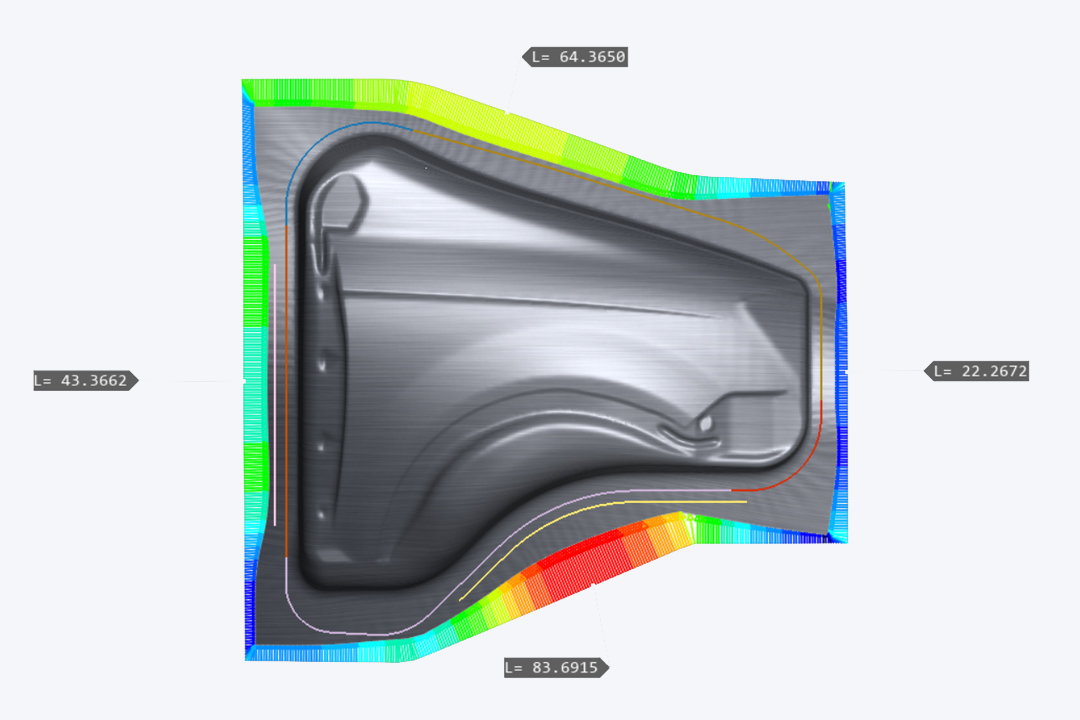

Structural Optimization

Ansys Mechanical offers parametric, shape (mesh morphing), and topology optimization features. Any model in Ansys Mechanical can be used to drive a parametric optimization.

Any model in Ansys Mechanical can be used to drive parametric optimization. Shape and topology optimization capabilities allow for the creation of efficient geometries, which can be transferred to CAD for production or other simulation work. Additive manufacturing, weight reduction, and robust design are excellent use cases for this technology.

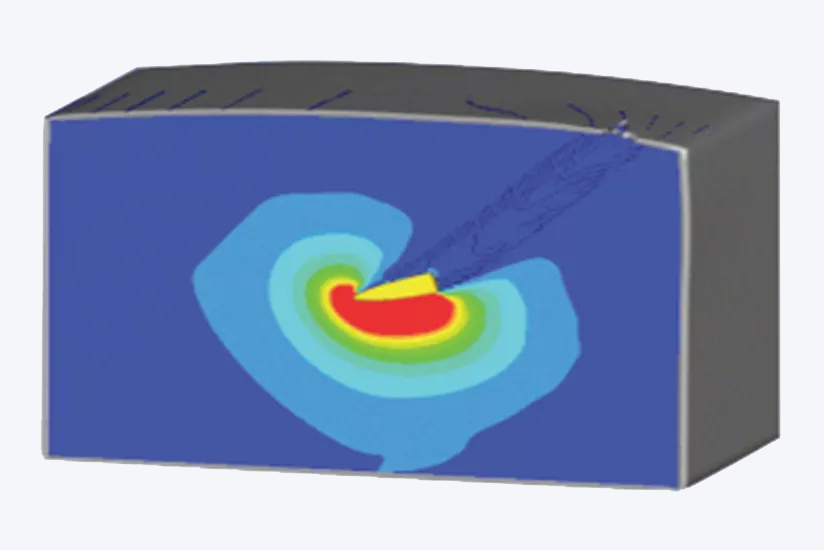

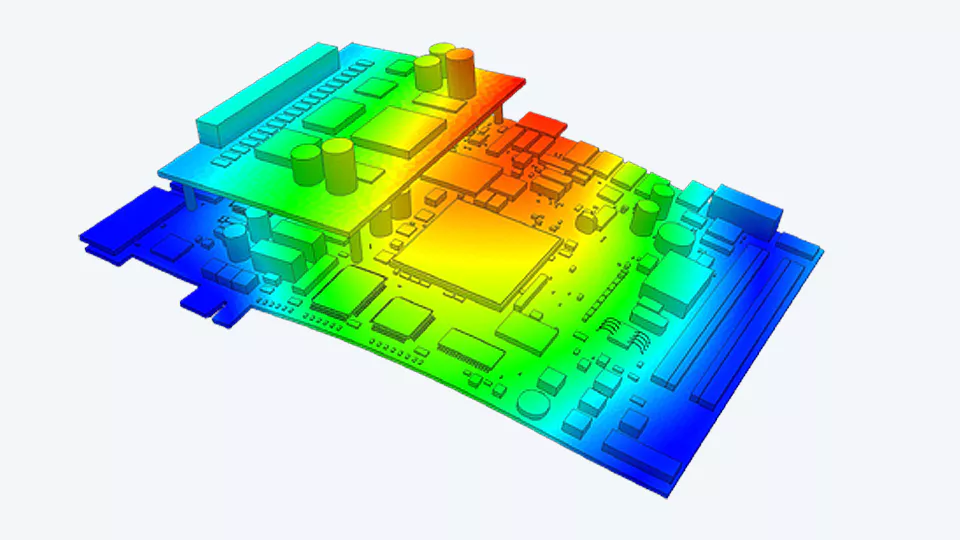

Thermal Analysis

Simulating heat conduction, convection, and radiation through assemblies allows you to predict the temperature of components, which can be used to examine the resulting stresses and deformations.

Ansys Mechanical allows you to read power losses or temperatures calculated from other analysis systems or files, meaning that CFD or electromagnetic simulations can serve as a starting point for thermal analysis. It is also possible to account for fluid flow in pipes and heat generated by friction between parts. All these capabilities enable more accurate simulations and better results.

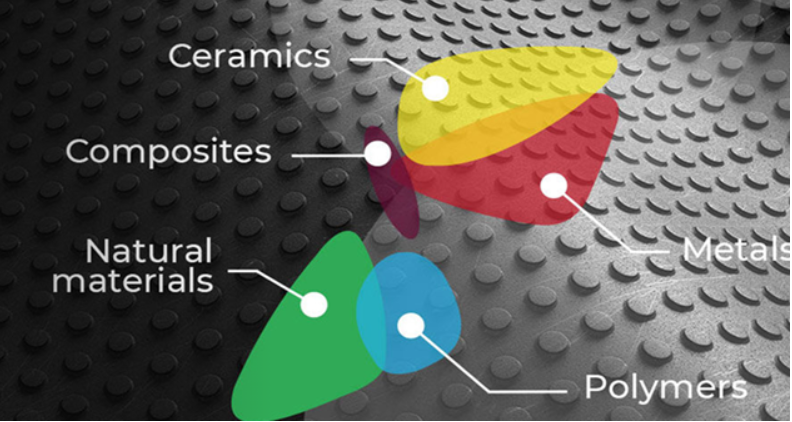

Materials

A range of material models, from hyperelastic to shape-memory alloys, as well as soils, concrete, and plastic and metallic structures, can be accurately modeled in Mechanical.

You can also add user-defined material models if needed. Granta Materials Data for Simulation provides instant, clickable access to the material property data you need, eliminating the time spent searching for data and reducing input errors. Material Designer can easily create representative volume elements (RVEs) based on lattice, fiber, weave geometries, or user-defined designs to facilitate multi-scale modeling of complex material structures.

Composites

Ansys Mechanical allows for the modeling of short fiber composites using data from upstream manufacturing simulation tools.

Ansys Mechanical allows for the modeling of laminated composites through its connection with Ansys PrepPost (ACP), and short fiber composites through integration with upstream manufacturing simulation tools and material behavior data obtained from Material Designer, Ansys’ tool for multi-scale homogenization of material microstructures.

You can generate composite models for implicit and explicit structural, thermal, and fluid simulations. Ansys Composite PrepPost (ACP) is the Ansys tool dedicated to modeling composite assemblies and analyzing failures. ACP offers efficient first-order solid element modeling capabilities and a platform with extensive options for exchanging model information. It supports the IAO composite HDF5 file format, which is vendor-independent, for communication with third-party tools, many of which are dedicated to and linked to composite manufacturing. Beyond composite structure modeling, Ansys Composite Cure Simulation (ACCS) simulates the curing process during manufacturing. ACCS is an extension of Ansys Mechanical that helps you simulate the curing process of a part and predict the residual stresses and distortions induced by the process to perform compensation analyses.

Hydrodynamics (Ansys Aqwa)

Ansys addresses the vast majority of analysis needs associated with the hydrodynamic evaluation of all types of offshore and marine structures.

This includes SPARs, FPSOs, semi-submersibles, jack-up rigs, ships, renewable energy devices, and breakwaters. Our product, Ansys Aqwa, has been widely used in the oil and gas, renewable energy, and general engineering sectors to model the installation and operation of equipment in open seas as well as in ports or sheltered locations.

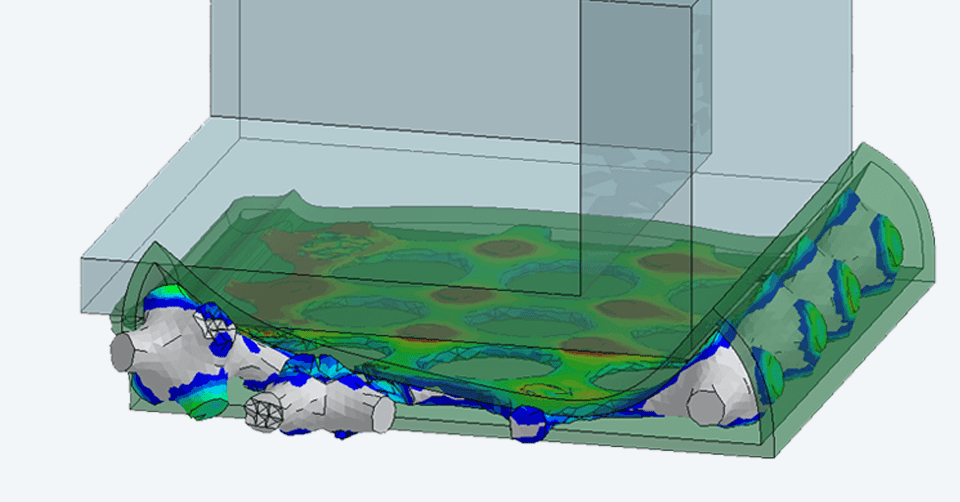

Fluid-Structure Interaction (FSI)

Accurately predict the interactions between fluids and solids under the influence of pressure and/or thermal loads. When fluid-structure interaction increases and the problem requires a more detailed evaluation, Ansys provides automated and easy-to-use solutions for both unidirectional and bidirectional coupling.

Unidirectional coupling solves the initial CFD or Ansys Mechanical simulation and automatically transfers the data to the other system. In a bidirectional coupling simulation, the fluid and structural simulations are set up and solved simultaneously, with data automatically transferred between the two solvers to achieve robust and accurate results.

Customization and Script Creation

The fastest and easiest way to tailor your simulation workflows. Customization within Ansys Mechanical allows you to automate repetitive tasks or specific workflows and share them among users.

The journaling and scripting features enable rapid development and easy training of new scripts.

More Ansys Solutions for Structural Mechanics

OUR REFERENCES

We are experts in various simulation techniques, and are committed to transferring our skills to your teams. Our aim is to help you successfully complete your simulation project.

CADFEM - A single source for your simulation needs

With over 35 years' experience in simulation, CADFEM is your trusted partner for a wide range of structural mechanics simulations.

Whether you need static strength analysis or the application of specific material properties, CADFEM's simulation expertise is at your disposal for your design projects.

With over 50 different training courses, we provide you with the skills you need to tackle areas such as structural mechanics, thermics, acoustics, and more. We also offer personalized consulting services. Get quick access to a wide range of software and licenses tailored to your needs.

To learn more about our training courses, please visit our dedicated page.